In the latter part of the nineteenth century, Portland Cement was made at Masons Cement Works in Waldringfield on the Deben. The ingredients were coke (a form of coal), chalk and mud. The only locally available material was mud. The accounts of the landowners, the Wallers, from 1885 show a lot of this being removed and as owners of the extraction rights they received payment from the cement works for it.

The area where the mud was dug is known as Hemley Point and Early Creek. From a 1956 account, we read:

‘There was no more familiar sight on the Deben, fifty to sixty years ago, [written in 1950s] than that of the old mud barge, the Kingfisher, leaving the Quay. Old Jack Stebbings was the skipper and Ben Page, brother of the Newbourn giant, was his mate. Their favourite place for getting the mud was opposite Whitehall Farm where, so said Jack,

“The mud had very little grit in it, and it dug up just like pork lard.”

During their twenty-five years of mud¬shovelling, they cleared over ten acres. Going out with the ebb tide, they waited, till the bottom was visible, then one loading fore and the other aft, they shovelled up twenty-five tons of mud before the tide returned, taking from three to four hours. Not bad going! They certainly-deserved a chunk of bread and cheese and a drink of home-brewed while they waited for the “Muddy” to float. Incidentally, Jack Stebbings, quiet on water, could be a terror on land and was well known in the local inns for his pugilistic ability.’

W Tye. A Guide to Waldringfield and District. 1956

‘End of life’ barges were favoured for this task. Kingfisher, built 1878, was young to be in this category so may have been specially built for the task. Poles or withies were set, so that the location could be seen when positioning the barge near high water. The skipper, Jack, or John, Stebbings lived in Cliff Road near the factory.

These ‘muddies’, as the diggers were known, would take the ebb to the site to be dug, settle the barge, and dig the mud They used a ‘flytool’ to dig spits and could simultaneously have; one landing, one in the air and be digging a third1Flytool –website Muddies in the Medway. Lime cloths were put around the mast and dead eyes to reduce mess. Care had to be taken to spread the load otherwise the hull would hog or sag.

Barges loading clay had baffle boards to stop it from slumping in the hold. A kedge anchor was laid to help pull free when loaded and a chain passed under the hull to break the suction holding down the hull: they would re-float and return with the flood. The rising tide would assist the return to the Quay where the mud was offloaded from the barge and tipped into the washmill. Not quite a nine-to-five job.

Over about twenty-five years the plant produced 320,000 tons of cement clinker which required 490,000 tonnes of dry raw material. This needed 112,000 tonnes of dry clay2Cement Production -Personal communication with cementkilns.co.uk: Mud with a density 1.84. If, as Walter Tye wrote, they extracted ten acres, or 40,000 square metres, of mud to a depth of, say, 1.5 metres then this would make 110,000 tons of mud, agreeing well with the total production of the Cement Works over its lifetime. The ten-acre rectangle overlaid on the Bing Earth image of the area, only for comparison, agrees broadly with Tye’s account. The notes section shows a modern LIDAR derived contour map of the area.

The 1888 Waller accounts show 175 loads being charged at £27 17s 6d and in the following year, 199 loads at £24 7s 6d. There were additional charges for water use as well as shingle and sand3Suffolk Record Office Waller Account Book.. This amount of mud, given a load of around twenty-five tons, over a period of twenty-five years, would require just under two hundred trips in a year on average. An interesting consideration is when they might do this work. They would need to leave the works at, say, before half ebb, settle, dig, re-float, and return by the last of the flood4110,000 tons over 25 years = 4400 tons per year. Say, 185 loads per year gives about 25 tons per load. This seems feasible for two strong men. The Medway ‘muddies’ dug 100 tons between a gang of eight or nine men in a tide which makes 12.5 tons per man per tide. .

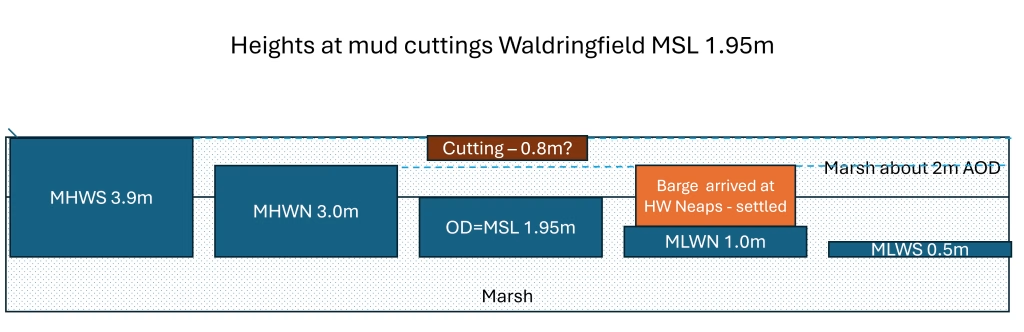

Even with the short distance of just over a mile from the works, this would take most of one tide of just over twelve hours. Positioning the barge and then leaving by tender to return later, would be possible but would be laborious. The work would need to be done largely in daylight. The diagram below shows the relative heights of the marsh and sea at Waldringfield which is virtually the same.

If the mud had been dug from the marsh upriver then at half flood the barge would ride up on the flood, anchor, settle at LW, dig the mud, float off near HW and then need to return on the ebb unless sailing was possible. This would take at least 16 hours for a digging cycle5half flood to HW to LW to HW plus, probably part of the ebb.. Cutting from down river is much more efficient.

The cycle of Spring tides, with high water around noon, and Neap tides with low water around noon, would affect the timing significantly, especially in the Winter. Obviously, the work was extremely strenuous but the timing considerations must have made it even more onerous. Given the vagaries of the weather, it seems probable that Jack and Ben6See Hugh Alker Tripp would have needed some help to dig this much mud. Anyway, hats off to them!

Notes

Notes on site, contours are AOD – 0m= Mean Sea Level, so high tide could be up to the 2m contour.

Footnotes

For more on Cement Works see Cement Kilns: Waldringfield

See HISTORIES OF THE HOO PENINSULA for mud digging.

F.G. Willmott, Cement, Mud and Muddies, a History of APCM Barges

- 1Flytool –website Muddies in the Medway

- 2Cement Production -Personal communication with cementkilns.co.uk: Mud with a density 1.84

- 3Suffolk Record Office Waller Account Book.

- 4110,000 tons over 25 years = 4400 tons per year. Say, 185 loads per year gives about 25 tons per load. This seems feasible for two strong men. The Medway ‘muddies’ dug 100 tons between a gang of eight or nine men in a tide which makes 12.5 tons per man per tide.

- 5half flood to HW to LW to HW plus, probably part of the ebb.

- 6See Hugh Alker Tripp

Image Sources and Credits

Image Credits and Sources

- 100_Objects_GM_Fly_Tool-3408-1147×765-1: GUILDHALL MUSEUM, ROCHESTER

- 1Flytool –website Muddies in the Medway

- 2Cement Production -Personal communication with cementkilns.co.uk: Mud with a density 1.84

- 3Suffolk Record Office Waller Account Book.

- 4110,000 tons over 25 years = 4400 tons per year. Say, 185 loads per year gives about 25 tons per load. This seems feasible for two strong men. The Medway ‘muddies’ dug 100 tons between a gang of eight or nine men in a tide which makes 12.5 tons per man per tide.

- 5half flood to HW to LW to HW plus, probably part of the ebb.

- 6See Hugh Alker Tripp

Image Credits and Sources

- 100_Objects_GM_Fly_Tool-3408-1147×765-1: GUILDHALL MUSEUM, ROCHESTER